Product lifecycle management (PLM) is an information management system that integrates data, processes, business systems, and, people in an extended enterprise.

PLM software allows to manage this information throughout the entire product lifecycle efficiently and cost-effectively: from ideation, design, and manufacture to service and disposal.

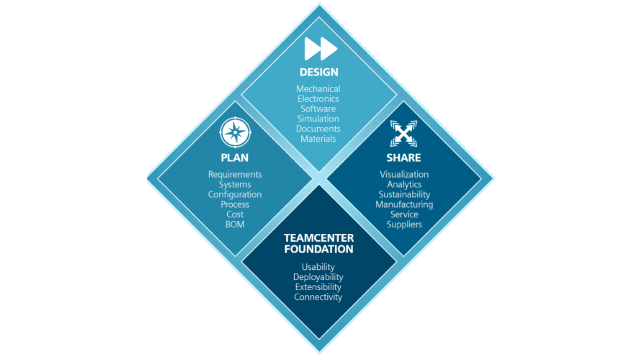

Product Lifecycle Management (PLM) Software to plan, design and share innovation.

PLM can be used to increase output with constant resources, to increase revenues or to reduce the resources used to produce a constant output. ... PLM helps organisation to achieve this through: Efficiency improvements. Improving development for new products

A PLM Strategy

PLM can be viewed as both an information strategy and as an enterprise strategy.

Information strategy: PLM builds a coherent data structure by consolidating systems.

Enterprise strategy: PLM lets global organizations work as a single team to design, produce, support, and retire products while capturing best practices and lessons learned along the way.

PLM empowers your business to make unified, information-driven decisions at every stage of the product lifecycle.

At Siemens Digital Industries Software, we believe it’s not enough just to digitize your processes since it only mimics processes digitally for incremental improvement.

You need to digitalize: weave a digital thread through ideation, realization, and utilization, and make that digital thread of knowledge a proactive agent in driving your business. With a fully optimized digital enterprise, you are better equipped to initiate or respond to innovation.

Applications of PLM Software

PLM solutions establish a cohesive digital platform to:

Optimize relationships along the product lifecycle and across organizations

Set up a single system of record to support diverse data needs, so that the right people see the right information at the right time and in the right context

Maximize the lifetime value of your business' product portfolio

Drive top-line revenue through repeatable processes

Comments